For some reason I am too busy doing things to have any great desire to write about them. I guess I’m not the only one…

Well, I did finally get my heated bed built and it worked the first time without any problems. I am using a 220vac silicon heating mat that has adhesive backing that allows attaching it to my aluminum heating plate (4mm). I am using a 0,9mm GFK printing plate that works great for both PLA and ABS. The best thing since sliced bread. I am currently only printing with PLA and glass also works great as a printing surface but the GFK printing plate only weights a few grams and is less than 1mm thick. The glass (4mm) almost weighs more than the aluminum plate.

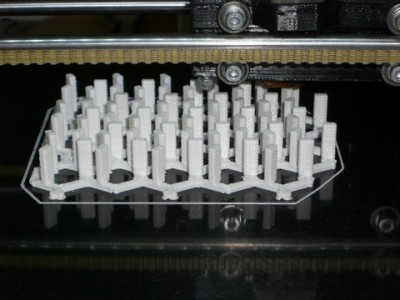

I got a request for an object via email from someone in Karlsruhe that wants a specific object to attach to the backside of a printed circuit board.

You can also see my Black GFK printing plate!

Last November (2011) I was in Atlanta, GA visiting my sisters and nieces over Thanksgiving and also arranged to meet my favorite EE professor (John B. Peatman) from my alma mater Georgia Institute of Technology (GA Tech). I wanted to give him something made with my RepRap so I printed a GA Tech Yellow Jacket logo.

Considering I had to pause the print and change the filament by hand I think it turned out pretty well. It would have been impossible without the heated bed.

The last several weeks my Z axis was not moving properly as if it was loosing steps. This happened suddenly as a printed out two very large objects (naked lady RGB mood light) which turned out perfectly and then when printing the same gcode files they were only 5/6 the height that they were supposed to be!

Well, last night I finally searched for and found the cause of the problem; two teeth were broken off the Z stepper motor T5 gear so I replaced it with one out of aluminum (it certainly won’t break again).