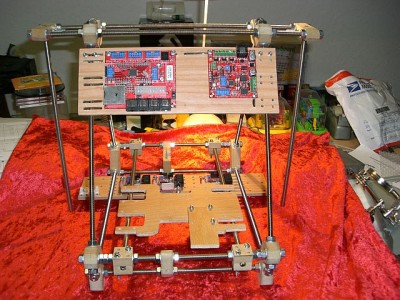

Well it’s been over a month since my last blog entry and I have managed to accomplish quite a bit with the help of several individuals.

After unsuccessfully trying to obtain the Mendel RP parts I made contact with Hans Reiner Ott (Holzwurm in the RepRap forums) who is self employed and has a workshop near Hamburg, Germany.

He had started to do a wooden Mendel and his first pieces looked very nice (posted in the German User Group). He was already assisting some others and he said that making a few extra copies was no problem so I received my first delivery of Mendel parts made out of MDF.

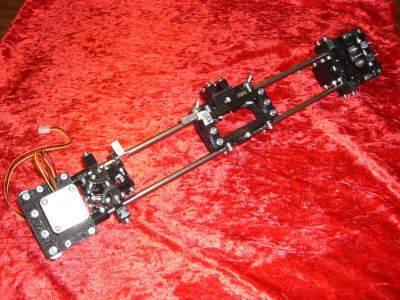

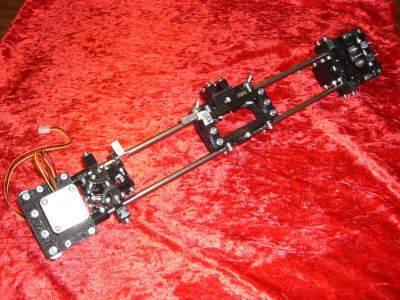

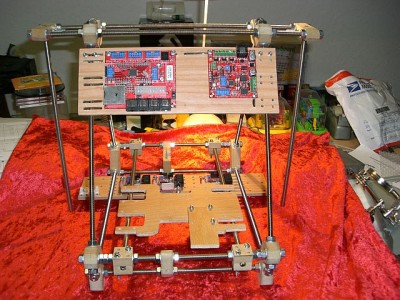

While Reiner was figuring out how to simplify the Y-axis to be able to create it with wood and plastic I was contacted by Stefan Maurer (RepRapParts) and asked if I still needed RP parts (which of course I did). So, since Holzwurm was already working on how to create Y-axis parts RepRapParts started making RP parts for the X-axis. Several days later he was ready to ship the parts. As soon as I received them I constructed my Mendel X-axis.

While Reiner was figuring out how to simplify the Y-axis to be able to create it with wood and plastic I was contacted by Stefan Maurer (RepRapParts) and asked if I still needed RP parts (which of course I did). So, since Holzwurm was already working on how to create Y-axis parts RepRapParts started making RP parts for the X-axis. Several days later he was ready to ship the parts. As soon as I received them I constructed my Mendel X-axis.

Motor and 360 Bearing:

Extruder sled:

Idler and 180 Bearing:

Around the same time as RepRapParts I had contact with Markus Amsler who offered to create the necessary RP gears for the motors and Z-axis for only the cost of shipping. He has made this offer to the RepRap community because he has successfully built a wooden Mendel and this was a serious stumbling block to his progress. So I arranged to get two sets: one for myself (rhmorrison) and one for Holzwurm. I sent Reiner his set and had also had sent to him a complete set of bearings for his Mendel.

Then Reiner let me know that it would be a while with the Y-axis parts because he was going to have a busy week and he wouldn’t be mad if I got Stefan to also make the Y-axis parts. So the deal was made and yesterday I received the Y-axis parts and immediately assembled it.

Reiner already had the Z-axis parts created (before he started on the Y-axis) and wanted to send them to me but his wife drove around with the package in her car for a couple of days so Reiner decided to wait to send the Z-axis parts until he received the belt splitter jigs that he is receiving from another German RepRapper. These parts I am waiting for to be able to complete the mechanical construction of the Mendel Cartesian Robot.

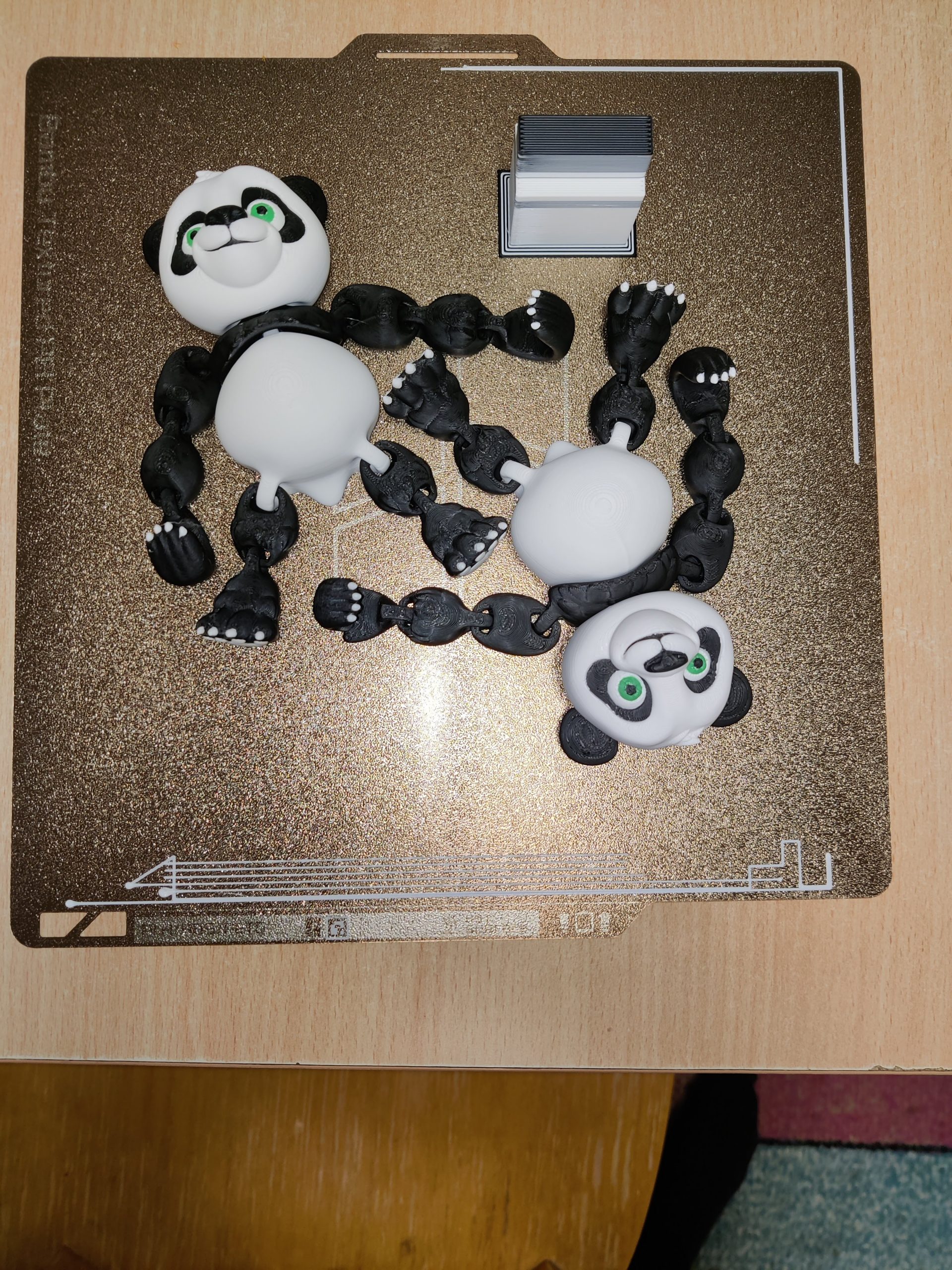

I also received notification from the customs office that they are holding a package for me. This is two Wade Nema17 geared extruders that was shipped on March 19, 2010 by RustySpoon1121 (see his offer in the forums)! So I will try to pick this up on Monday, April 12, 2010 and I can then assemble two extruders: one for me; the other for Reiner (his will have everything except the motor, he has enough of those).

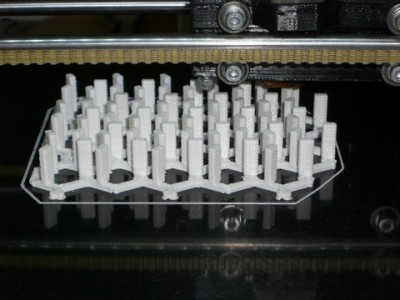

So what’s next on the schedule – while waiting for the Z-axis parts and the belt splitter jig that I desperately need I can modify the electronics (change from MakerBot to RepRap design) and possibly do some initial hardware tests. Before I can send Reiner his extruder I must fully test it to make sure that it extrudes without any problems.

That’s all Folks!

).

).

While Reiner was figuring out how to simplify the Y-axis to be able to create it with wood and plastic I was contacted by Stefan Maurer (

While Reiner was figuring out how to simplify the Y-axis to be able to create it with wood and plastic I was contacted by Stefan Maurer (